品質と効率を追求する現代の産業では、適切な材料を選択することが成功のために非常に重要です。当社のポリエチレン (PE) フォーム素材は、低密度、優れたクッション性、優れた耐水性、優れた成形性を備えており、熱成形プロセスに理想的な選択肢であり、お客様の製品を市場で目立たせることができます。

PEフォーム素材の優れた特性

1.高性能密度

· 密度範囲: 20 - 100 kg/m3

· 利点: 当社の PE フォーム素材は軽量でありながら堅牢であるため、熱成形によって形成されたパッケージと部品が製品に余分な重量を加えず、十分な強度を確保できます。

2.優れた引張強度と圧縮強度

・引張強さ:0.15~0.35MPa

・圧縮強度:0.02~0.10MPa

· 利点: PEフォームの強力な引張および圧縮性能により、成形および使用中の高い耐久性と信頼性が保証され、変形や損傷を効果的に防止します。

3.優れた熱安定性

・軟化温度: 80°C - 100°C

· 利点: 当社の PE フォーム素材は優れた熱安定性を示し、熱成形プロセスの高温下での分解や変形を防ぎ、スムーズな生産を保証します。

4.優れた耐水性・耐湿性

· 吸水率: < 0.05%

· 利点: PE フォームの独立気泡構造により、優れた耐水性と耐湿性が確保され、湿気保護が必要な用途に適しています。

5.高効率の断熱・防音

・熱伝導率: 0.035 - 0.045 W/m・K

· 音響伝送クラス (STC): 15 - 25

· アドバンテージ:優れた断熱性と遮音性により、建設業界と自動車業界の特定のニーズを満たし、市場での製品競争力を高めます。

6.環境特性と安定性

· 特性: 無毒、低 VOC、高いバッチ間の一貫性

· 利点: 環境基準に準拠し、各バッチで高い一貫性を維持しながら安全で信頼できる生産プロセスを確保し、それにより生産効率を向上させます。

市場アプリケーション: 複数の分野に最適なソリューション

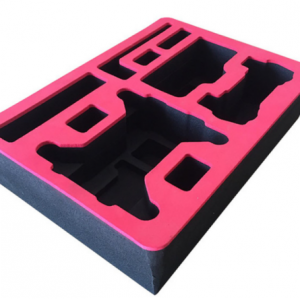

1.電子製品のパッケージング

ハイエンドエレクトロニクス市場では、製品を保護するために高品質の梱包材が非常に重要です。当社の PE フォーム素材は、優れた耐衝撃性、防湿性、軽量性を備えています。熱成形技術を使用して、内張りは製品の形状に正確に適合し、輸送中の安全性と完全性を確保します。

· 利点: 衝撃保護、耐湿性、軽量

· 用途: ハイエンドのスマートフォン、タブレット、精密電子部品のパッケージング

2.家電

家電製品のパッケージには、材料に対する厳しい性能基準が求められます。熱成形によって加工された当社の PE フォーム素材は、優れた衝撃緩衝性、湿気保護、高い熱安定性を提供し、パッケージが機器の形状に正確に適合することを保証します。

· 利点: 耐衝撃性、湿気保護、熱安定性

· 用途: 冷蔵庫、電子レンジ、エアコンの包装ライニング

3.建築断熱

建設業界では、エネルギー効率と環境への配慮が中心的なニーズです。当社のPEフォーム素材は断熱性、耐水性に優れ、軽量なので施工や使用が簡単です。

· 利点: 断熱性、耐水性、軽量

· アプリケーション: 建物の壁および屋根の断熱層

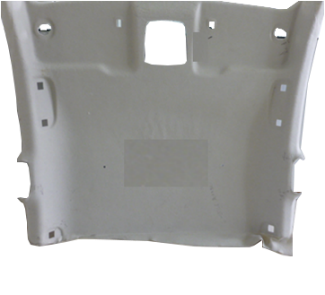

4.自動車産業

自動車産業では、軽量で多機能な材料が求められています。熱成形技術を利用した当社の PE フォーム素材は、自動車の内装や衝撃吸収部品に広く使用されており、部品が自動車の設計に正確に適合し、車両全体の性能が向上します。

· 利点: 軽量、耐衝撃性、環境特性

· 用途: 自動車内装、シートパッド、バンパー保護

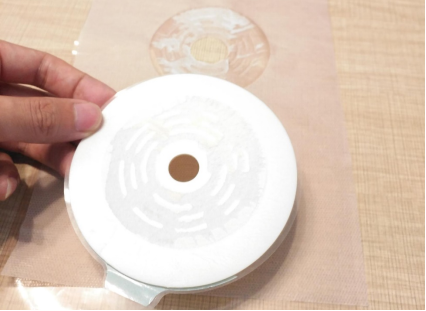

5.トロピカルフルーツパッケージ

トロピカルフルーツの包装分野でも、当社の PE フォーム素材は理想的な選択肢です。トロピカルフルーツの包装の内側ライニング保護として、熱成形技術を使用することで、ライナーが果物の形状に完全に適合し、世界中に安全に鮮度を届けることができます。

· 利点: 衝撃保護、耐湿性、軽量

· 用途: トロピカルフルーツの包装裏地

詳細について、またはカスタマイズされたソリューションについてのお問い合わせについては、お気軽にお問い合わせください。

お問い合わせ

· メール: info@yufapolymer.com

· ウェブサイト: www.yufapolymer.com

一緒に輝きを生み出すパートナーとなることを楽しみにしています。