Case Study: Material Selection for EV Battery Pack Protection

�� Client Background

· Industry: Electric Vehicle Manufacturer

· Requirement: Reliable battery pack protection with weight reduction and cost control.

❌ Customer Challenge

The client needed a foam material that could:

· Withstand high heat and vibration

· Provide strong shock absorption

· Ensure lightweight automotive foam design

· Stay cost-efficient for large OEM orders

3. Our Solution

Yufa Polymer designed a custom metallic shielding bag with the following specifications: ✅ Our Solution

We analyzed EPP, IXPP, and MPP:

· EPP: good impact resistance but limited heat tolerance

· IXPP: excellent heat performance but high cost

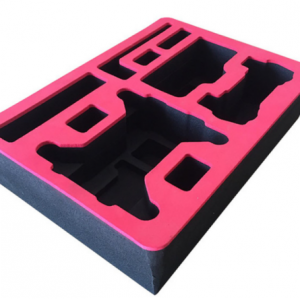

· MPP foam: best balance – superior thermal resistance, great impact absorption, lightweight, and cost-effective

We delivered custom-sized MPP foam panels for battery pack bottom protection.

�� Results & Customer Feedback

· Enhanced durability & thermal stability

· Successful impact and vibration tests

· Lower overall cost vs. IXPP

· Customer confirmed MPP as their long-term choice for battery pack protection

�� Key Takeaway

With deep material expertise, Yufa Polymer helps OEMs select the right solution for their applications. For automotive energy storage, MPP foam stands out as today’s mainstream option for lightweight automotive foam in battery pack protection.

�� Contact us to learn more about MPP & IXPP.

YUFA Polymer Products Co., Ltd.

�� Address: Shenzhen, China

�� Email: info@yufapolymer.com

�� Web: www.yufapolymer.com